- sales@streborfire.com

- 01202 886797

Hydrants

Specification

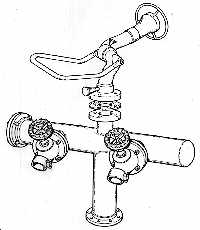

Dry Barrel Pillar Type Hydrant, Four Outlet

Strebor Fire Hydrant shall meet or exceed AWWA C502-80 and includes the following features as required by overall design criteria.

Hydrant shall be:

fabricated from 150mm dia sched 40 carbon steel pipe to api standard 5l grade b complete with schedule 40 butt weld cap to ansi B16.9 / BS1640.

Inlet shall be:

150mm dia ansi type B16.5 class 150 / BS504 PN16 RF

Outlet shall be:

4 x 65mm dia with flanges 3"ASA 150 FF each outlet controlled by a pressure hydrant control valve of gunmetal construction to maintain outlet pressure in the range 4.1 - 5.5 bar. Valve outlet shall be 65mm dia female instantaneous to BS336. Valves shall be fitted with blanking cap and chain.

1 x 6" ASA 150 FF flange. Shall be fitted with gunmetal adaptor flanged 6" ASA 150 FF to 5.5" LRT female and shall be fitted with blanking plug and chain.

1 x 3" ASA 150 Flanged FF shall be fitted Strebor J Type Gunmetal Monitor with 600 J Type Fog / Jet Nozzle.

Rotation : 360 degrees

Vertical: -30 deg to +90 deg

Locking: Manual hand knob Vertical & horizontal

Throw: 53 metres jet stream @ 10 bar

Fog / Jet: Variable through 120 degrees

Adjustment: Manual adjusting ring

Material: Monitor - Gunmetal LG2;

Nozzle - Engineeering copolymer composite.

Fire Hydrants shall be galvanised internally and externally for protection against corrosion to BS729

Final finish shall be two pack polyurethane type isocyanate free air drying paint colour red to BS5398

Working pressure: 7 - 10 bar

Design presure: 13 bar

Hydrostatic test pressure: 20 bar

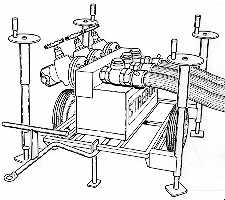

Twin Outlet

Portable Hydrant